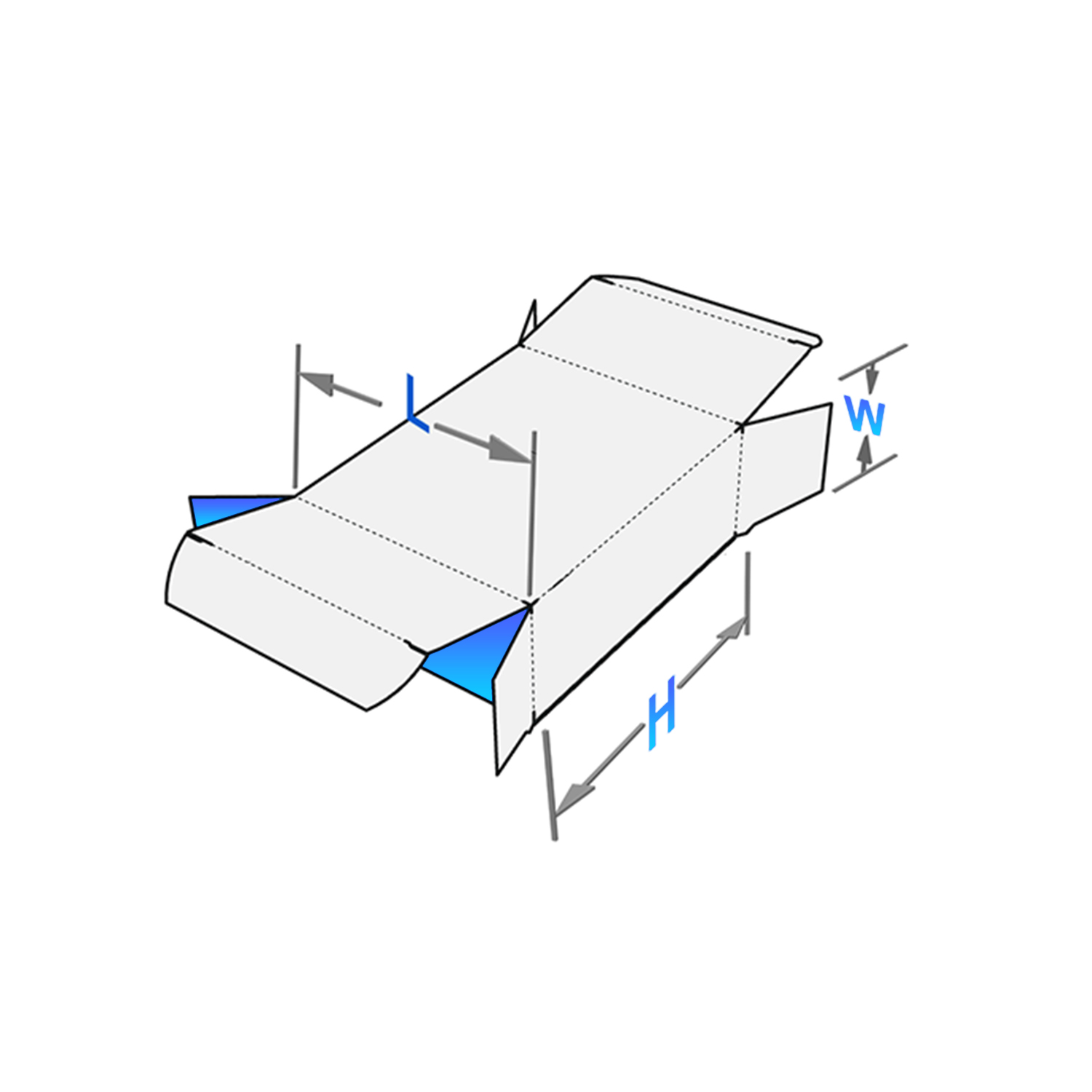

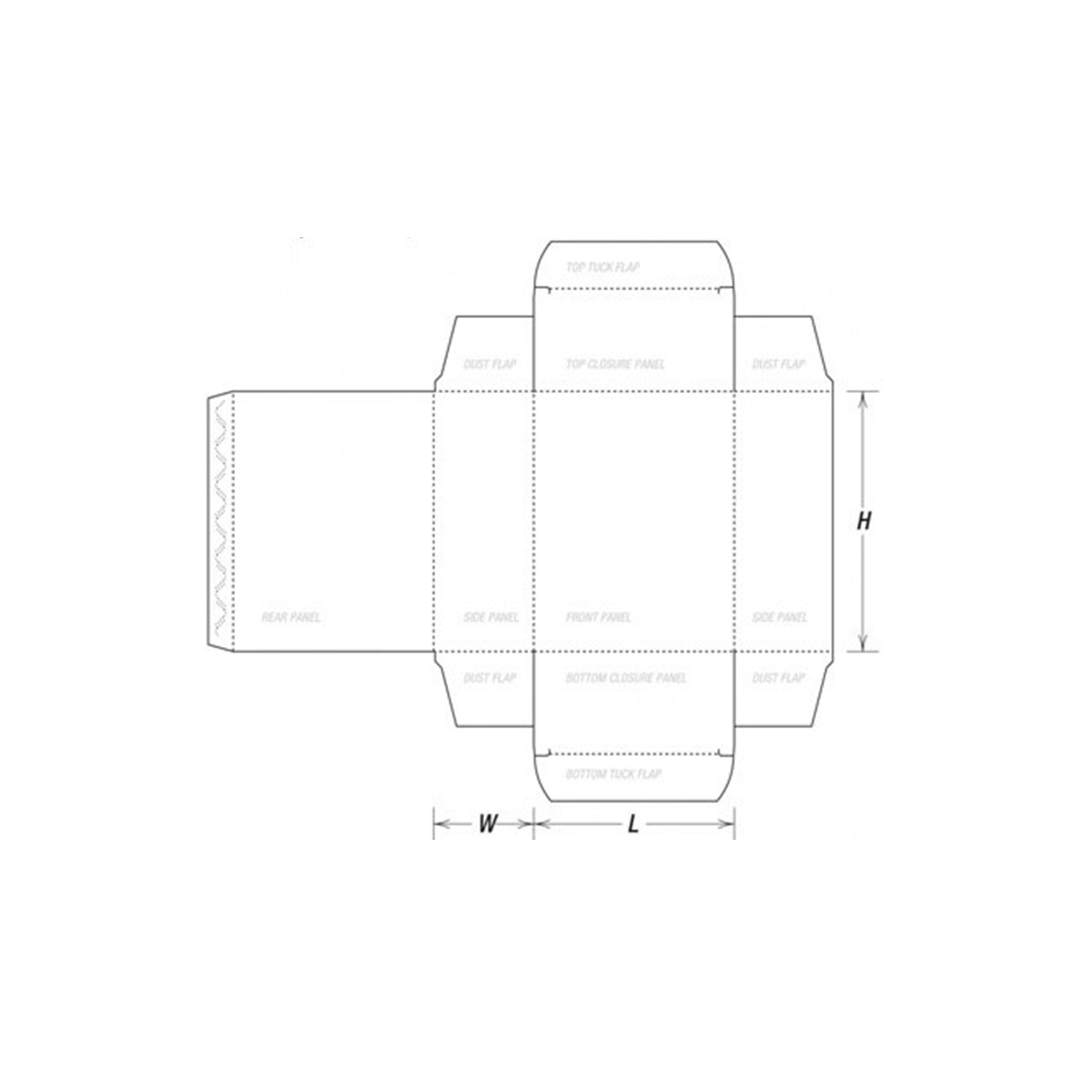

Straight tuck end (STE)

Straight tuck end boxes, also known as straight tuck end cartons, are an ideal packaging choice for various products that require both a main display panel and an optional convertible window panel. The tuck closures are positioned behind the back of the straight tuck end box, giving it a clean and seamless appearance. These straight tuck end cardboard boxes are designed with raw edges located along both ends of the front display panel, which are cleverly concealed to ensure a refined finish.

At Boxes One, we offer custom straight tuck end packaging solutions with high-quality straight tuck end boxes printing to enhance your brand visibility. Whether you need retail packaging or display-ready boxes, our straight tuck end boxes provide functionality, durability, and a premium presentation for your products.

Box Style | Punch Partition, Tuck Flap Box, Pillow Box, Gable Box, Sleeve Box |

Dimension (L + W + H) | All Custom Sizes Available |

Quantities | 100 – 500,000 |

Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

Printing | Plain, CMYK Colors, PMS (Pantone Matching System), Spot Colors |

Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling |

Included Options | Die Cutting, Gluing, Perforation |

Additional Options | Embossing, Window Patching, (Gold, silver, Copper, Red, Blue Foil Stamping) |

Proof | Flat View, 3D Mock-up, Physical Sampling (On request)

|

Turnaround | Standard Turnaround Time:After getting the artwork approved, it takes 5-7 business days for producing the box and further 5-7 business days for the shipment to be conveyed. While in the case of corrugated boxes and folding cartons the turnaround time is between 15-22 business days which include 10-15 business days for the production of boxes and 5-7 business days for the shipping to reach your doorstep. When talking about rigid boxes the production time is increased to 25-30 business days and so is the shipping time from 25-35 business days. Expedite Turnaround Time:Once the job is sent for production after the approval of artwork the production time for corrugated boxes and folding cartons is 8-10 business days whereas shipping requires 5-7 business days. In case of rigid boxes, the expedited turnaround time varies as per the quantities and will be quoted accordingly. |

Shipping | Ship Flat, Packed in Boxes, UPS, Fedex, DHL |

If your graphic files do not meet our specs, BoxesOne will not be charged for any resulting typographical errors. Read our artwork preparation to prepare your records for submission, or contact us for help from a packaging professional!

Cut & Crease Line (Red Lines):

Represents the section in its final size and where the box should be folded. Related graphics and text should be placed at least 0.125 inches from the cut line.

Bleed Line (Blue Lines):

Shows whether the drain section is located. All graphics that run up to the cut line should be extended to the cut line for a clear print.

Safety Margin(Green Lines):

Defines where to safely place illustrations and text. As an business standard, all illustrations should be well-ordered at least 0.125 inches from the cut line unless your design is proposed.

Perforation (Dotted Black Lines):

The broken line indicates to paper punched with very small cuts to make it more comfortable to cut and fold the paper.

- Choose your order product packaging in our library.

- Request a custom quote (Box/Product dimensions, Required Quantity)

- Get your custom Dyelines by knowing any of our representatives through email or live chat.

- Prepare Your Artwork Designs Let your creativeness run stormy because now is the time to design your effort of art on any custom floorboards. Our professional graphic designers will examine your designs and make a 3D digital model from scratch of your packaging for your review and satisfaction before starting to manufacture your order.

- Place your order Once the digital design proof is approved and payment is made so we just need 8-9 business days for productions and 1-2 days for ground shipping.

- Production process begins after the payment is made.

Straight Tuck End (STE) Boxes – Custom Packaging for UK Businesses

At Boxes One, we specialise in manufacturing Straight Tuck End (STE) boxes that combine durability, ease of use, and premium presentation. Designed for both manual and automated packing, our custom straight tuck end (STE) packaging is perfect for UK businesses looking to showcase their products with style and efficiency.

Whether you’re in cosmetics, pharmaceuticals, retail, or food packaging, our STE boxes offer a professional look, secure closure, and endless customisation options — ensuring your products stand out on the shelves.

What is a Straight Tuck End (STE) Box?

A Straight Tuck End box features tuck flaps on both the top and bottom that close in the same direction, creating a sleek, seamless appearance. This design not only enhances the visual appeal but also ensures quick assembly and secure closure.

Key benefits of the STE design:

- Premium presentation – Smooth front panel with no raw edges showing.

- Easy to pack – Suitable for both hand and machine packing.

- Versatile applications – Ideal for lightweight to medium-weight products.

- Cost-effective – Minimal material wastage during production.

- Customisable – Available in various sizes, materials, and finishes.

Why UK Businesses Choose Boxes One for Custom Straight Tuck End (STE) Packaging

1. Tailored to Your Brand

Your packaging is your silent salesperson. We help you design custom straight tuck end (STE) boxes that reflect your brand identity — from printed logos to vibrant colours and high-quality finishes.

2. Flexible Order Quantities

Whether you need a small run for a product launch or large-scale production for nationwide distribution, we offer scalable packaging solutions to meet your needs.

3. Premium Materials & Finishes

We use high-grade paperboard, kraft, and eco-friendly materials that maintain shape and print quality. Finish your STE boxes with:

- Gloss or matte lamination

- Spot UV coating

- Embossing or debossing

- Foil stamping

4. UK-Based Support & Fast Turnaround

Our UK-based packaging experts ensure clear communication, quick prototyping, and fast delivery across the country.

5. Sustainability Commitment

We prioritise eco-friendly packaging options without compromising quality — perfect for businesses aiming to reduce their environmental impact.

Applications of Straight Tuck End (STE) Boxes

Our custom STE packaging is widely used in:

- Cosmetics & Beauty – Creams, serums, perfumes

- Pharmaceuticals & Healthcare – Medicine, supplements

- Food & Confectionery – Chocolates, teas, snacks

- Retail & E-Commerce – Electronics, gadgets, accessories

Customisation Options

We provide full creative freedom to design your straight tuck end STE boxes exactly how you envision them:

- Dimensions – Tailored to fit your product perfectly

- Printing – Full-colour CMYK or Pantone

- Window cut-outs – Showcase your product inside

- Internal printing – Enhance the unboxing experience

Why Straight Tuck End (STE) Boxes Outperform Other Styles

- Better Shelf Appeal – Front panel stays smooth and clean

- Efficient Assembly – Saves packing time and costs

- Dual-Side Accessibility – Easier product insertion and removal

- Secure Closure – Protects products in transit

Order Your Custom Straight Tuck End Boxes Today

At Boxes One, we combine precision manufacturing with creative design to deliver straight tuck end packaging that works as hard as your products do. Get a free quote today and see how we can help your brand stand out.

FAQs – Straight Tuck End (STE) Boxes

Q1: What’s the difference between Straight Tuck End (STE) and Reverse Tuck End (RTE) boxes?

A: STE boxes have top and bottom flaps that close in the same direction, giving a neater front panel. RTE boxes have flaps that close in opposite directions, which can slightly expose raw edges.

Q2: Can I order small quantities?

A: Yes, we cater to both small-batch and bulk orders to suit your business needs.

Q3: Are STE boxes suitable for heavy products?

A: STE boxes are best for lightweight to medium-weight items (up to around 200g). For heavier products, we recommend reinforced or alternative box styles.

Q4: Do you offer eco-friendly STE packaging?

A: Absolutely. We offer recyclable, biodegradable, and FSC-certified materials.

Q5: How long does it take to receive my custom boxes?

A: Standard orders are typically delivered within 7–10 business days after approval, with express options available.