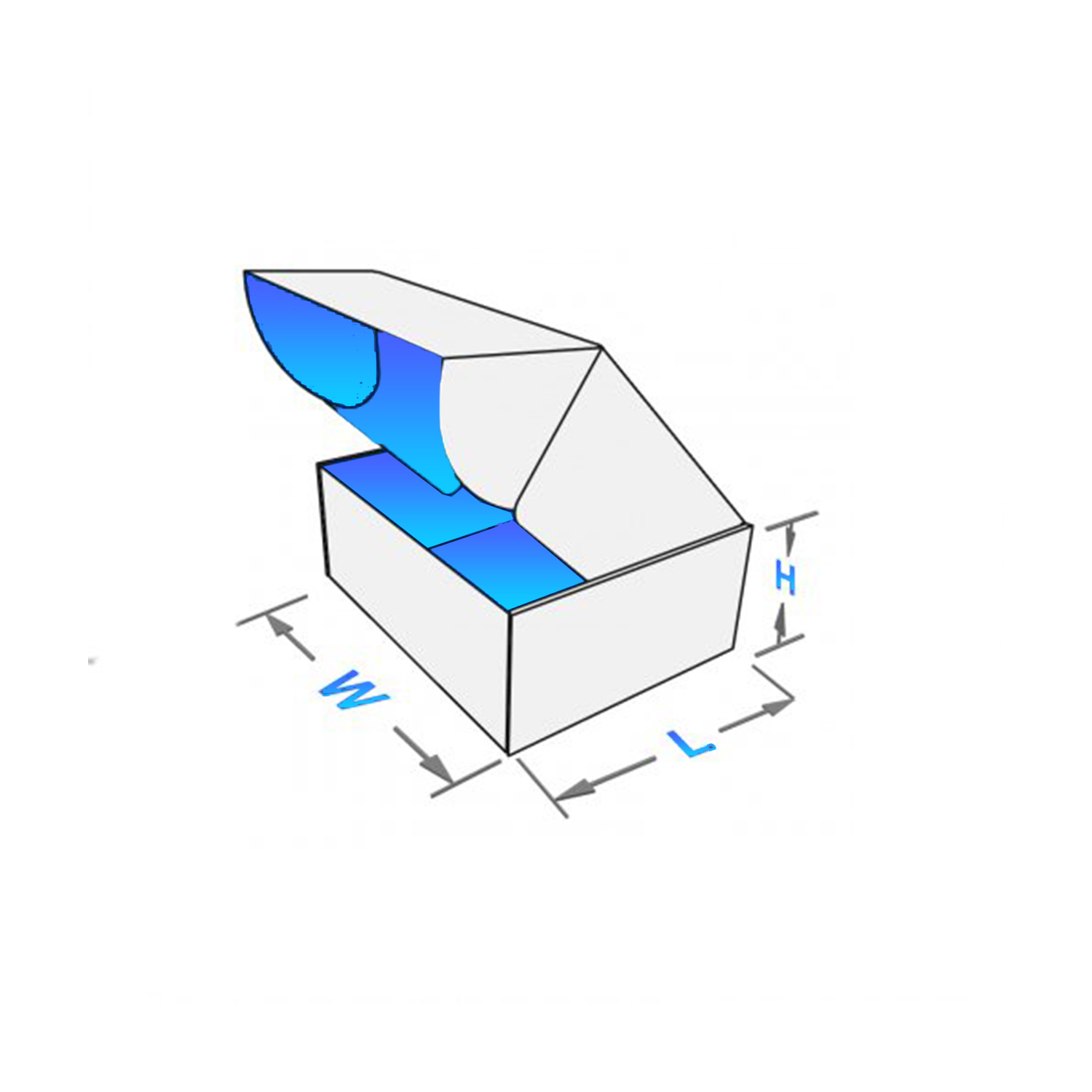

Double wall tuck front

Double-wall tuck front boxes are created with no glued lid and tray. The presence of side panels allows them to be rolled to get the box in a complete shape. An extra front panel is extended from the lid of double wall tuck front boxes and has two locking tabs. These boxes are strong in nature that making them perfect for use with heave load contents.

Box Style | Punch Partition, Tuck Flap Box, Pillow Box, Gable Box, Sleeve Box |

Dimension (L + W + H) | All Custom Sizes Available |

Quantities | 100 – 500,000 |

Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

Printing | Plain, CMYK Colors, PMS (Pantone Matching System), Spot Colors |

Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling |

Included Options | Die Cutting, Gluing, Perforation |

Additional Options | Embossing, Window Patching, (Gold, silver, Copper, Red, Blue Foil Stamping) |

Proof | Flat View, 3D Mock-up, Physical Sampling (On request)

|

Turnaround | Standard Turnaround Time:After getting the artwork approved, it takes 5-7 business days for producing the box and further 5-7 business days for the shipment to be conveyed. While in the case of corrugated boxes and folding cartons the turnaround time is between 15-22 business days which include 10-15 business days for the production of boxes and 5-7 business days for the shipping to reach your doorstep. When talking about rigid boxes the production time is increased to 25-30 business days and so is the shipping time from 25-35 business days. Expedite Turnaround Time:Once the job is sent for production after the approval of artwork the production time for corrugated boxes and folding cartons is 8-10 business days whereas shipping requires 5-7 business days. In case of rigid boxes, the expedited turnaround time varies as per the quantities and will be quoted accordingly. |

Shipping | Ship Flat, Packed in Boxes, UPS, Fedex, DHL |

If your graphic files do not meet our specs, BoxesOne will not be charged for any resulting typographical errors. Read our artwork preparation to prepare your records for submission, or contact us for help from a packaging professional!

Cut & Crease Line (Red Lines):

Represents the section in its final size and where the box should be folded. Related graphics and text should be placed at least 0.125 inches from the cut line.

Bleed Line (Blue Lines):

Shows whether the drain section is located. All graphics that run up to the cut line should be extended to the cut line for a clear print.

Safety Margin(Green Lines):

Defines where to safely place illustrations and text. As an business standard, all illustrations should be well-ordered at least 0.125 inches from the cut line unless your design is proposed.

Perforation (Dotted Black Lines):

The broken line indicates to paper punched with very small cuts to make it more comfortable to cut and fold the paper.

- Choose your order product packaging in our library.

- Request a custom quote (Box/Product dimensions, Required Quantity)

- Get your custom Dyelines by knowing any of our representatives through email or live chat.

- Prepare Your Artwork Designs Let your creativeness run stormy because now is the time to design your effort of art on any custom floorboards. Our professional graphic designers will examine your designs and make a 3D digital model from scratch of your packaging for your review and satisfaction before starting to manufacture your order.

- Place your order Once the digital design proof is approved and payment is made so we just need 8-9 business days for productions and 1-2 days for ground shipping.

- Production process begins after the payment is made.